The Plummer Compressors Approach

Combining over 20 years of expertise, resources and skills, Plummer Compressors provides services that are tailored specifically to support your business efficiently and effectively.

Combining over 20 years of expertise, resources and skills, Plummer Compressors provides services that are tailored specifically to support your business efficiently and effectively.

Something’s in the air

Oftentimes clients will approach Plummer due to issues with air quality or air pressure. This may be an issue you’ve experienced intermittently that has slowly grown over time, or perhaps is fine one day but not the next – with no clear cause. Low air pressure is usually a key signifier to an issue, which may be a factory-wide problem or more likely an issue isolated to one machine.

What are the first steps?

When you engage the services of Plummer, the first step is to always discuss and understand your problem, which will be unique to you and your business. This can be conducted by phone to identify key issues, after which we may offer suggestions to help you identify the root cause of the problem. This is a great way for business owners and managers to be more aware of issues they may face going forward so that they can troubleshoot and rectify any problems before they become critical.

If the problem is more complex or requires more resources than you have available, Plummer can organise a site visit to help scope the issue. During the site visit, it’s imperative for Plummer to be shown everything which may help the investigation including the machine/s in question, what exactly is happening, and when it is happening. There are generally a lot of questions asked during these site visits to ensure we have a detailed knowledge of your operations. By viewing the actual machine(s), we will be able to gain valuable insights into air usage and how the air supply to it is configured.

Proposing a tailored solution

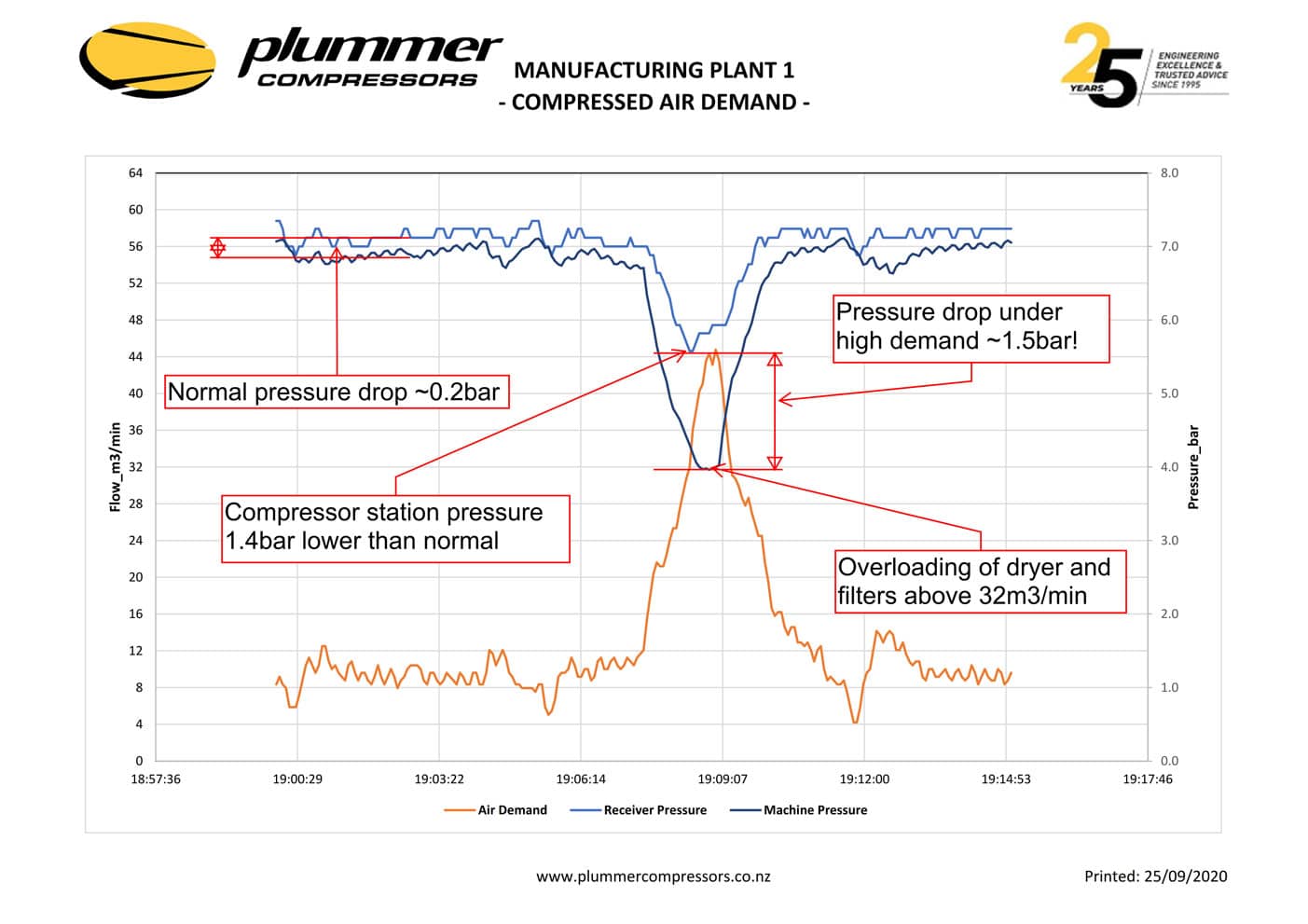

After completing a site visit, we will likely have a good sense of the potential root causes. Sometimes it can be a little more challenging if a problem is intermittent, but if this is the case we can offer data logging which is usually conducted during a time period sufficient to capture most operations within the factory. Care needs to be taken to record the correct information e.g. pressures and airflow, at what location and what time resolution.

Compressed air systems are dynamic systems, so pressure will vary with compressed air flow rate. What may be fine one day, maybe a problem on the next due to differing air consumption. It is not uncommon for site personnel to have a good sense of what the problems are, but having actual data and graphs typically proves pivotal to support recommendations for remedying the issues at hand.

Plummer Compressors is well-positioned to provide accurate data and expert analysis with multiple pressure, flow, and compressor data loggers available.

Services customised to your needs

We are big believers in tailored and customised solutions. No two factories are the same, and therefore our services are customisable to suit the needs of the issue at hand as opposed to a one-size-fits-all solution.

Plummer Compressors prides itself on providing accurate information and data regarding the pros and cons of various solutions. Our mission is to ensure the best outcome and service for each individual situation and customer, rather than shoehorning clients into a fixed product or service.

By educating our customers and compressed air users as we work together on a solution, we aim to ensure they have accurate and relevant information to make the best decision for their needs. We empower our clients to understand the problem, the solution and how it works best for their needs.

Through our consultation process and site visits, we engage with each client to obtain all the relevant information and date required. By combining this with our expertise, knowledge and training, the Plummer Compressors team is well-versed to provide the best advice for each of our customers on a case-by-case basis.

24/7 Support

Our customers benefit from 24-hour support for air compressor breakdowns and maintenance. Calls to one number – 09 2743550 – reach our technicians along with our extensive range of stand-by air compressors to restore your production facilities promptly.

Case Study: Metalcraft Insulated Panels

New Compressor Not Required

New Compressor Not Required

Project Description:

Metalcraft Insulated Panels Ltd requested the services of Plummer Compressors to investigate an intermittent problem with their compressed air system. It was suspected that the compressor may have become too small for the growing requirements of the factory.

In order to properly understand the situation Plummer Compressors recommended that a data logger be installed on the air compressor to record actual factory air demand over the course of a week or more.

Analysis of the data revealed the following:

- Compressor average duty cycle was less than 40%

- Nil production demand was approx. 15% of compressor capacity

- Intermittent large spikes in demand were noted

Plummer Compressors carried out further investigation to identify the source of the spikes in air demand and ultimately it was traced to a vacuum lifter for sheets of metal, which has 52 vacuum cups with 26 compressed air powered venturi vacuum pumps.

Three issues became apparent during our observations & research:

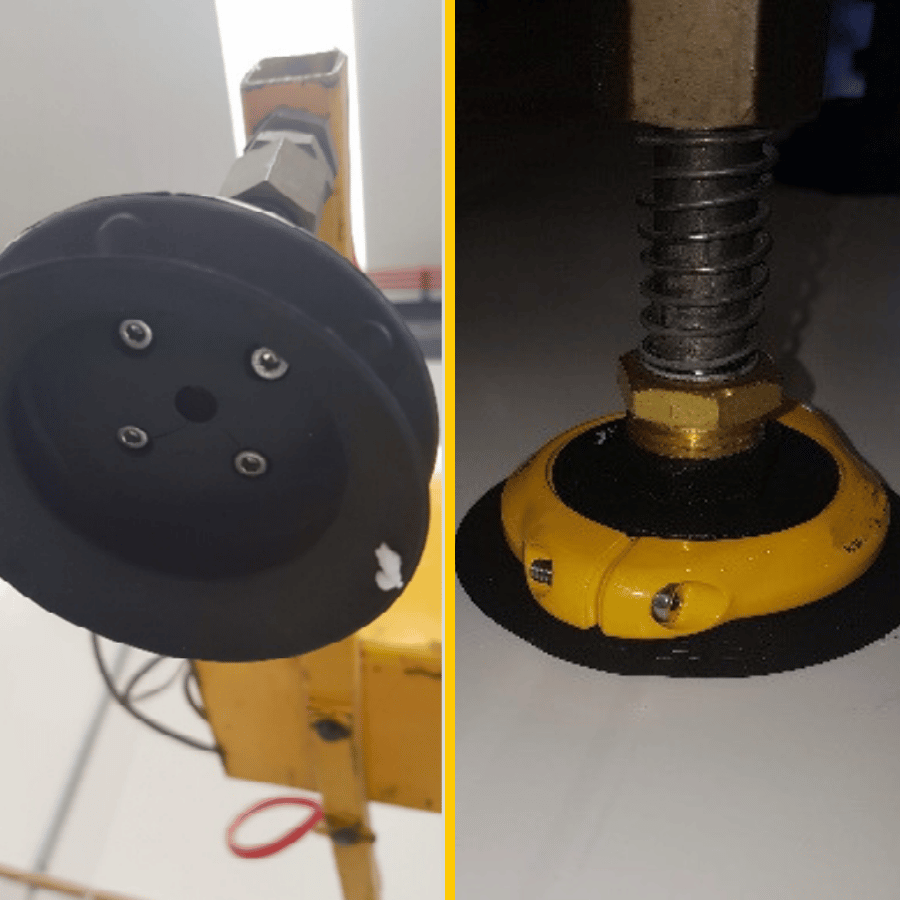

Old Style Vacuum Cup

- Some of the vacuum cups were in a deteriorated condition

- The vacuum cups were a convoluted type that were not always holding the sheet in a stable manner, whereas the original cups were the flat type

- During lifting of shorter sheets of metal some of the vacuum cups do not press on to metal sheet but are left exposed – creating a huge vacuum leak

Metalcraft carried out Plummer Compressors recommendations to replace the vacuum cups with flat cups with an internal shut-off valve that open only on contact with a lifting surface. There was no loss in cup performance even with ridges on the metal sheets. Air pressure to the new cups could be reduced due to the improved performance with no open cups, which resulted in a decrease in air consumption.

Follow-up logging showed a drop in peak air demand, leaving spare compressor capacity for future requirements. Metalcraft were very happy they called on the expertise of Plummer Compressors to analyse, diagnose and resolve their problem without pressure for the purchase of a new compressor.

Common Air Compressor Supply Issues & How To Solve Them

Do you have occasional (or regular) problems with machinery which you believe could be a result of your air compressor supply?

Hopefully not, but periodically we have customers calling us seeking assistance with what they believe could be a compressed air supply problem. Symptoms can be a machine with unreliable performance or perhaps shutting down due to low pressure from a sensor.

Aside from verifying the fault is real, the primary question everyone should ask is: what is the root cause?

In terms of compressed air, this generally means asking “is it a compressed air distribution problem or is it a compressed air supply problem?”

PRESSURE GAUGE

If you are having problems that may be related to compressed air, then your go-to tool is the pressure gauge. It is essential to have a reliable and readily visible pressure gauge at the supply point of the machine to allow you to fault-find effectively. If the gauge is always in view, the supply pressure can be regularly monitored and if there is a machine problem the pressure can be observed immediately. If you find you do have low pressure at the machine at the same time you are experiencing a problem then yes, maybe your compressed air could be a contributor. As a nominal figure, most pneumatics are designed to work at a minimum pressure of around 6bar, so if you are significantly lower than this, then problems are more likely.

Now that you’ve verified there is a real compressed air problem, the next step is to determine the root cause for the low pressure – is it a distribution or supply issue?

DISTRIBUTION

What we are referring to here is an excessive pressure drop between the air compressor station and the point of use.

The simplest way to begin to verify if you have a big pressure drop is the go-to tool – the pressure gauge. Spend some time in front of the compressor (and receiver) and get familiar with the pressure range that the air compressor works at, then compare it with what you measure in the factory.

If at all possible, use the same hand-held pressure gauge – this will eliminate differences between gauges. Ideally, your pressure drop between the compressor and machine should be less than 0.5bar (7psi). If you’re significantly above this then you need to find the cause – it might be time to call in some assistance at that point (that’s us!).

One very important point to remember, the pressure drop is related to the flow rate in the pipe. If you have no or little flow then there will be no pressure drop, but as your flow increases so does the pressure drop. So it is critical you measure the pressure drop under normal operating conditions.

Now let’s consider supply.

SUPPLY

Essentially what we’re asking here is are you running out of compressor capacity? To determine this you generally have to spend a little time at your compressor or compressors and observe what is happening. Before you start though, you need to know what sort of control system your compressor uses – the three main possibilities are: load/unload, variable speed or modulating control.

Load/Unload:

This style of compressor will cycle between two pressures, coming onload at one pressure and pumping the system up to a higher pressure, where it unloads. If your compressor is loading and unloading regularly then that tells you there is some spare capacity.

If you actually time the compressors load and unload times and work out the percentage of time on load then by default you know the spare capacity i.e. if you determine the compressor is on load 80% of the time, then you know you have 20% spare capacity. Click here to download a generic timing & calculation sheet we have developed – it is actually for leak calculations but you can equally use it for duty cycle calculations.

By giving us your compressor details we can tailor a calculation sheet specifically for your compressor – get in touch with us here. If you observe this compressor not coming off load for long periods and the pressure is not increasing (or periodically decreasing), this indicates it may be at the limit of its output i.e. you are using all the air it can make.

Variable speed:

When you stand next to this type of compressor you will generally hear the unit speeding up and slowing down. If your system is set up well, this type of compressor usually maintains a relatively stable pressure.

If the unit is unable to maintain that pressure – or more particularly the pressure is dropping below the usual set point, then this is a good indicator the unit may be hitting full capacity but still not keeping up.

Modulating control:

This style of compressor is a little less common now (and it can be very inefficient), but essentially it throttles the air intake to vary the compressor output. It can be difficult to confirm if a compressor is modulating control but again, if you know the normal pressure range it runs at and then observe the system pressure falling consistently below this, it is a strong indicator that the compressor may be at the limit of its output.

To summarise the issue of supply, if you find the compressor is operating flat out and its discharge pressure is falling low at the same time you are having machine problems, there’s a high possibility you have a supply (capacity) problem. Note that compressors can recover quite quickly – if there’s a fault at a machine and it then stops, by the time someone gets to the compressor to see what it’s doing it may well have recovered and be back up to pressure.

I’ll also point out here that although a compressor running flat out and not keeping up suggests a supply problem, it isn’t always the true picture – it may be there is a substantial leak or unusual demand (e.g: stuck valve).

To see the full picture when it looks like many issues could be a factor, carrying out real-time logging of pressures – both at the compressor and in the factory – can be the best way to determine conclusively what is happening and therefore ensure you implement the right solution.

We have a selection of pressure and compressor logging equipment, so are well resourced to help you determine what is really happening.

Please talk to us and we’ll gladly work with you to plot the way forward to a plant free from compressed air problems.

The quest for high quality compressed air – Three key steps

When it comes to compressed air, air quality is of the utmost importance. All compressors need to undergo regular servicing in order to deliver superior air quality and improve the functionality of both your system and its components.

If you don’t implement some air quality controls, such as dryers and filters, then you will be at the mercy of both machine and environmental conditions. All air compressors draw in contaminated air, and most air compressors are fluid lubricated, so if nothing is done to manage what passes through to the compressed air network adverse contamination can result.

If you don’t implement some air quality controls, such as dryers and filters, then you will be at the mercy of both machine and environmental conditions. All air compressors draw in contaminated air, and most air compressors are fluid lubricated, so if nothing is done to manage what passes through to the compressed air network adverse contamination can result.

Dryers are the most effective and most common compressed air treatment item and there are a range of options depending on applications and requirements. Filters are also a vital component in order to produce the air quality level the compressed air system needs. If your compressor is running hot, then you are at risk of higher moisture and greater oil carryover. With a filter in the system then, at the very least, you have a control point to mitigate fluctuating network air quality.

The ISO standard 8573-1 is a really good reference point, as this is how treatment components are specified. For more information on this quality standard download our guide here. By talking to one of our compressed air experts, they can explain the ISO standard and through asking some pertinent questions, they will guide you to the right treatment level for your circumstances.

Implementing your own internal “housekeeping” checks is vital to achieving proper air quality. Your compressed air service provider is not usually on site regularly, so there needs to be someone who is onsite to take responsibility for checking that everything is running normally.

Plummer Compressors recommends the following checks:

- If your air receiver is after a refrigerant dryer, implement a daily check where someone cracks the drain valve – if it is not dry then you have a problem.

- Have coalescing filters drain into a translucent bottle – if you glance at it periodically you will then notice if the bottle is suddenly full or rapidly filling.

- Create a logbook for the checks – this helps to make sure the checks do occur, plus there is then a record of what is normal when someone new completes the checks. Click HERE to contact us for free assistance in creating a log book specific to your system.

Once you have internal housekeeping protocols to follow, there are key steps you can implement to ensure you are producing the correct air quality for the applications you are running. Examples of air applications range from plant air – used to power pneumatic tools; process air, found in pharmaceutical and food industries; and breathing air which is used in spray painting and hospital air systems.

The three key steps that we recommend to take for ensuring the appropriate quality compressed air are as follows:

1. Determine what air quality level you need – What uses compressed air? What is the impact of water, oil or dust contamination for those users or contact points? Air quality is split into class ratings that cover the three main contaminants: oil, water and solid particles.

2. Talk to an expert who can assess whether your current treatment components meet that need. Ask site staff whether there have been any historical problems – as this may also identify any treatment weaknesses.

3. Install any changes and then implement your own set of checks (so you know the system is working) – as was outlined above.

The current economic climate means we are all facing new business challenges. Compressed air is generally an essential utility – if it stops, production stops. While cutting equipment maintenance in testing times may seem like a good idea in the short-term, it may be a choice that is regretted if it stops your entire production and results in larger resultant losses.

Air quality requirements vary from business to business but making sure you are producing the correct air quality for your applications needs to be a high priority, particularly if you want to do it in an efficient and cost-effective manner.

Get in touch with one of our compressed air technicians to discuss your needs.