Advanced Pneumatic Solutions for the Greater Auckland with Plummer Compressors & Festo

Advanced Pneumatic Solutions for the Greater Auckland with Plummer Compressors & Festo

Advanced Pneumatic Solutions for the Greater Auckland with Plummer Compressors & Festo

Empowering Greater Auckland Industries with Premier Pneumatic Technologies

Welcome to the leading edge of industrial pneumatics, where Plummer Compressors’ local expertise in Auckland unites with Festo’s global innovation. Together, we’re dedicated to advancing Greater Auckland industries with our comprehensive pneumatic solutions.

Our Expertise – Your Advantage

Fittings and Tube:

- Premium-quality fittings and tubes designed for the rugged demands of Greater Auckland industries.

- Key Features: Unmatched durability, versatile application, superior efficiency.

Compressed Air Preparation:

- State-of-the-art air preparation systems, ensuring your operations run with clean, efficient, and reliable compressed air.

- Key Features: Optimal performance, reduced energy costs, prolonged equipment life.

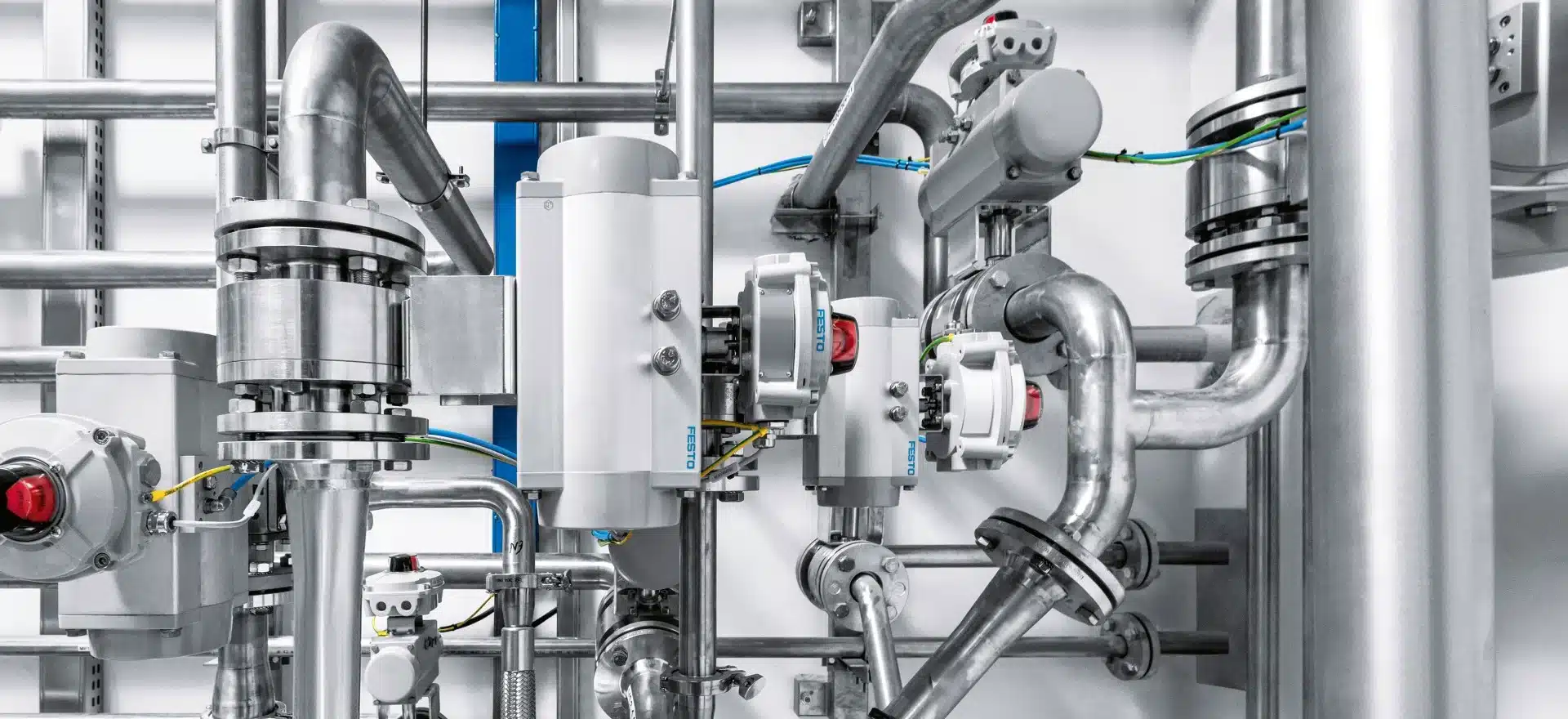

Valves:

- A diverse range of precision-engineered valves, tailored for precise control in demanding industrial environments.

- Key Features: Exceptional reliability, adaptable designs, cutting-edge technology.

Pneumatic Drives & Cylinders:

- Robust and adaptable drives and cylinders, built to meet the unique challenges of the North Island’s industrial sector.

- Key Features: High precision, durable construction, application versatility.

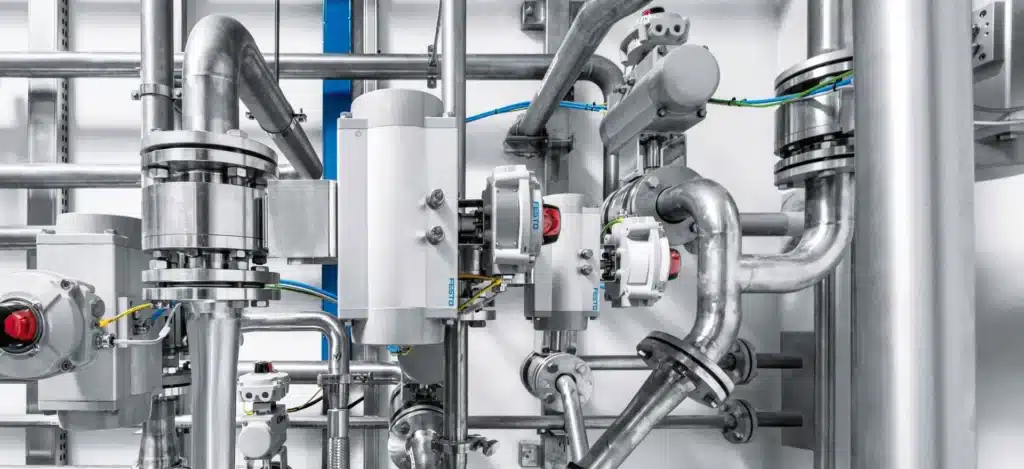

Process Valves and Actuators:

- Advanced process valves and actuators for streamlined automation, enhancing efficiency across various industries.

- Key Features: Unparalleled control, improved process efficiency, innovative designs.

Connect with the team at Plummer:

Festo New Zealand have realigned the way they do business by increasing their sales capacity, improving direct supply to customers from Australia and outsourcing their trade counter and local stock to their partners. We have strategically aligned with Festo in Auckland so that with our stock, trade counter, internal and external sales team as well as service technicians, we are able to provide leading service and expertise to the market.

These changes are in partnership with PSL Total Air (Christchurch) who are a long-standing official Festo partner, also offering customers in-person service and direct stock availability. For more information on Festo’s offerings in New Zealand, visit their website at Festo New Zealand.

Connect with our Auckland-based Plummer Compressors team for a consultation tailored to your business needs.

The Plummer Compressors Approach

Combining over 20 years of expertise, resources and skills, Plummer Compressors provides services that are tailored specifically to support your business efficiently and effectively.

Combining over 20 years of expertise, resources and skills, Plummer Compressors provides services that are tailored specifically to support your business efficiently and effectively.

Something’s in the air

Oftentimes clients will approach Plummer due to issues with air quality or air pressure. This may be an issue you’ve experienced intermittently that has slowly grown over time, or perhaps is fine one day but not the next – with no clear cause. Low air pressure is usually a key signifier to an issue, which may be a factory-wide problem or more likely an issue isolated to one machine.

What are the first steps?

When you engage the services of Plummer, the first step is to always discuss and understand your problem, which will be unique to you and your business. This can be conducted by phone to identify key issues, after which we may offer suggestions to help you identify the root cause of the problem. This is a great way for business owners and managers to be more aware of issues they may face going forward so that they can troubleshoot and rectify any problems before they become critical.

If the problem is more complex or requires more resources than you have available, Plummer can organise a site visit to help scope the issue. During the site visit, it’s imperative for Plummer to be shown everything which may help the investigation including the machine/s in question, what exactly is happening, and when it is happening. There are generally a lot of questions asked during these site visits to ensure we have a detailed knowledge of your operations. By viewing the actual machine(s), we will be able to gain valuable insights into air usage and how the air supply to it is configured.

Proposing a tailored solution

After completing a site visit, we will likely have a good sense of the potential root causes. Sometimes it can be a little more challenging if a problem is intermittent, but if this is the case we can offer data logging which is usually conducted during a time period sufficient to capture most operations within the factory. Care needs to be taken to record the correct information e.g. pressures and airflow, at what location and what time resolution.

Compressed air systems are dynamic systems, so pressure will vary with compressed air flow rate. What may be fine one day, maybe a problem on the next due to differing air consumption. It is not uncommon for site personnel to have a good sense of what the problems are, but having actual data and graphs typically proves pivotal to support recommendations for remedying the issues at hand.

Plummer Compressors is well-positioned to provide accurate data and expert analysis with multiple pressure, flow, and compressor data loggers available.

Services customised to your needs

We are big believers in tailored and customised solutions. No two factories are the same, and therefore our services are customisable to suit the needs of the issue at hand as opposed to a one-size-fits-all solution.

Plummer Compressors prides itself on providing accurate information and data regarding the pros and cons of various solutions. Our mission is to ensure the best outcome and service for each individual situation and customer, rather than shoehorning clients into a fixed product or service.

By educating our customers and compressed air users as we work together on a solution, we aim to ensure they have accurate and relevant information to make the best decision for their needs. We empower our clients to understand the problem, the solution and how it works best for their needs.

Through our consultation process and site visits, we engage with each client to obtain all the relevant information and date required. By combining this with our expertise, knowledge and training, the Plummer Compressors team is well-versed to provide the best advice for each of our customers on a case-by-case basis.

24/7 Support

Our customers benefit from 24-hour support for air compressor breakdowns and maintenance. Calls to one number – 09 2743550 – reach our technicians along with our extensive range of stand-by air compressors to restore your production facilities promptly.

Case Study: Metalcraft Insulated Panels

New Compressor Not Required

New Compressor Not Required

Project Description:

Metalcraft Insulated Panels Ltd requested the services of Plummer Compressors to investigate an intermittent problem with their compressed air system. It was suspected that the compressor may have become too small for the growing requirements of the factory.

In order to properly understand the situation Plummer Compressors recommended that a data logger be installed on the air compressor to record actual factory air demand over the course of a week or more.

Analysis of the data revealed the following:

- Compressor average duty cycle was less than 40%

- Nil production demand was approx. 15% of compressor capacity

- Intermittent large spikes in demand were noted

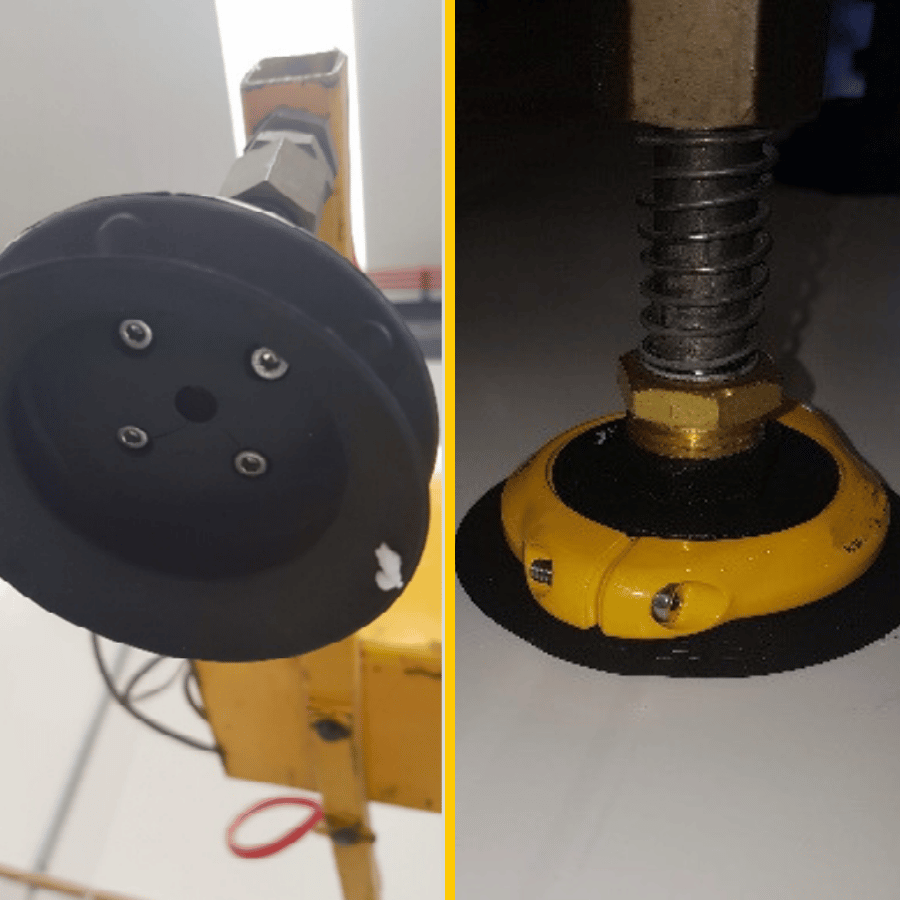

Plummer Compressors carried out further investigation to identify the source of the spikes in air demand and ultimately it was traced to a vacuum lifter for sheets of metal, which has 52 vacuum cups with 26 compressed air powered venturi vacuum pumps.

Three issues became apparent during our observations & research:

Old Style Vacuum Cup

- Some of the vacuum cups were in a deteriorated condition

- The vacuum cups were a convoluted type that were not always holding the sheet in a stable manner, whereas the original cups were the flat type

- During lifting of shorter sheets of metal some of the vacuum cups do not press on to metal sheet but are left exposed – creating a huge vacuum leak

Metalcraft carried out Plummer Compressors recommendations to replace the vacuum cups with flat cups with an internal shut-off valve that open only on contact with a lifting surface. There was no loss in cup performance even with ridges on the metal sheets. Air pressure to the new cups could be reduced due to the improved performance with no open cups, which resulted in a decrease in air consumption.

Follow-up logging showed a drop in peak air demand, leaving spare compressor capacity for future requirements. Metalcraft were very happy they called on the expertise of Plummer Compressors to analyse, diagnose and resolve their problem without pressure for the purchase of a new compressor.

Case Study: Wilco Precast LTD

Aluminium Pipe Installation

Project Description:

Wilco Precast LTD requested the services of Plummer Compressors to provide a solution for leaking underground air pipes at their South Auckland location. The site also required a major extension to the existing pipe system. This was to provide additional outlets in order to avoid safety issues from air hoses running across the floor at multiple points.

The solution to provide additional outlets on both the side wall of the factory, as well as running down the centre of the building, provided flexibility for production to be moved around the factory. This meant the client wouldn’t need to be concerned about having an air supply readily available.

The main challenges with the project were:

- achieving a fast install to minimise production disruption

- working at height (up to 9 metres above the ground)

- working around the concrete moulds permanently fixed to the floor

The Plummer Compressors team met with Wilco Precast management to formulate a plan and a successful outcome. Specialist height equipment had to be sourced to allow the new AIRCOM pipe to be installed onto concrete beams 9 metres above the floor of the factory. Two 4-wheel drive rotating telescopic boom lifts were selected, and used in tandem to install the pipe. With only centimetres between the rows of moulds on the floor, the lifts had to be skilfully manoeuvred as well.

The project went very smoothly using the AIRCOM aluminium pipe system and the solutions offered by the team at Plummer Compressors. The client was very satisfied with the completed project, which was completed on time and within budget.

Challenges:

Working at height

Working at height- Connection to existing pipework

- Minimising disruption to production schedules

- Weekend & after hours work

- Tight spaces & limited access

Outcomes:

- Utilised EWP licensed personnel

- Compatible with existing pipe

- Agreed plan with owner and production managers

- Use of specialty access equipment

- Completion on time and on budget